As modern technology evolves, more and more state-of-the-art fabrication technologies are introduced to production in order to achieve efficiency, quality.

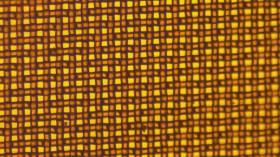

In filtration industry, SHARE is producing and supplying filter meshes and fabricated / converted mesh filters; Woven filter meshes can be fabricated into different shapes, such as ribbons or tubes.

Traditionally, ribbons are produced by slitting machine using cold knife, but this fabrication method will cause fraying problem, this is not acceptable in most of the industries requiring filtration, because frayed yarns could possibility detach from mesh pieces/ filter mesh ribbons into filtered fluid and get it polluted. Realizing this problem, hot knife slitting machine is introduced to slit mesh, compared with cold knife slitting, hot knife slitting can well prevent meshes from fraying, as slitting, mesh yarns are melted. But problems still exist if cleanliness required, such as food and medical industry, hot knife slitting can keep me from fraying, while heated knife can leave mesh

Continue reading