How to buy

To order or inquire about our products, please contact us or send us an inquiry

Introduction:

When nylon, polyester, polyethylene, polypropylene and other mono-filament fibers are woven into mesh screens very precise micron opening sizes are achieved.

These fabrics characteristically provide precision filtration results equally effective in wet or dry environments and are even used as sifting screens.

SHARE provides fabrics with filtration efficiencies from 7 microns up to 1,650 microns and fabricates sleeves, tubes, funnels, belts, bags and panels in any desired configuration and size.

Application:

1. Liquid Filtration

2. Vegetables/crops protection (insect mesh)

3. Fishing Farm

4. Farming

5. Road building

6. Waste Water Treatment

7. Chemical Processing Filters

A,B,C About the Mesh

1. Mesh: Designates the number of openings per inch (25.4mm)

2. Designates the measurement of the clear open space between parallel adjacent wires.

Opening Size=25.4 mm÷Mesh Count−Wire Diameter

Pitch=Opening Size+Wire Diameter; or 25.4mm÷Mesh Count

Open Area %=(Opening Size)2÷(Opening Size+Wire Diameter)2×100

3. Designates the diameter of wire before weaving. With a same mesh count, when the wire diameter is different, the opening size and open area are significantly changed.

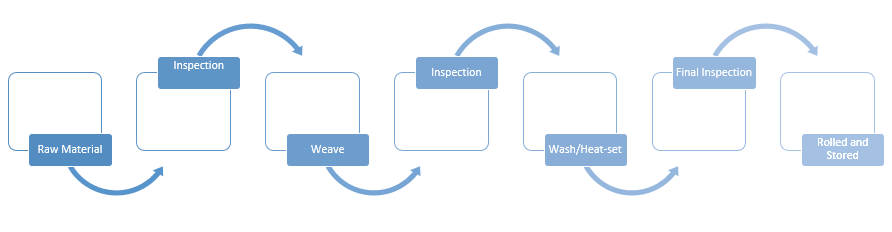

Production Procedure:

Chemical Resistance of Major Fibers

|

Polyethylene Woven Screen Mesh |

||||||||

|

Style Number |

Mesh Opening |

Mesh Count |

Thread Diameter |

Weight |

||||

|

Opening |

Opening Area % |

Inch |

Micro |

Per inch |

Per cm |

Inch |

micro |

oz/yd2 |

|

SH PE 1000 |

56 |

0.0394 |

1000 |

19.6 |

7.7 |

0.0118 |

300 |

3 |

|

SH PE 400 |

46 |

0.0157 |

400 |

43.2 |

17.0 |

0.0079 |

200 |

3.2 |

|

SH PE 300 |

26 |

0.0118 |

300 |

43.2 |

17.0 |

0.0079 |

200 |

3.9 |

|

SH PE 250 |

39 |

0.0098 |

250 |

63.5 |

25.0 |

0.0059 |

150 |

2.9 |