How to buy

To order or inquire about our products, please contact us or send us an inquiry

Introduction:

Woven by monofilament Yarn/threads, polyester screen printing mesh is seen wide applications in different industrial printing, such as glass printing, graphic printing, ceramic printing, paper printing, circuited board printing, plastics and packaging printing...

SHARE has been dedicating herself in research, development and production of high quality polyester printing mesh since 1983, importing Swiss Weave Looms and German Reeds to produce mono-filament polyester printing mesh, other than equipment, we also import quality yarns to weave mesh; Our trained workers, together with advanced machines, equipment, can weave high quality printing mesh; By improving our quality, we also are thinking of ways to reduce costs, so we can give our clients' lower price to reduce their production cost.

Advantages:

- Faster Tensioning without damage to the threads

- Improved fabric strength

- Faster Tension Stabilization

- Higher Tension threshold and breaking point

- Less tension loss during the stretching process

- Faster turnaround time from the screen room to the press room

- Improved registration due to stable tension

- Faster print speed

Characteristics:

- Screen printing makes it possible to print on wide range of substrates.

- Screen printing makes it possible to print on the substrates with various shapes and sizes.

- Many kinds of ink are available.

- Thick coating is possible. (General stencil: 10-30 microns, Special stencil: more than 100 microns)

- Thick coating makes colors more vivid, finish more opaque and light-fastness better.

- As printing pressure is small, it is possible to print on fragile matters.

- As the stencil is soft, it is possible to print on hard materials such as glass and metal as well as soft materials such as paper and fabrics.

- The stencil is cheap, which is the advantage in case of production of small quantity.

Applications:

Screen printing are being used for various substrates in various fields. Ink does not adhere to some kinds of substrates with other printing methods. Screen printing can be used on some of these substrates.

- Commercial applications:

Posters, billboards, POP, displays, stickers, signs, flags - Daily necessaries:

Toys, stationery, sports goods, bags, T-shirts, cosmetic containers, toiletry containers, packages, wooden products, glass, ceramics. - Industrial applications:

Automobile meters, CDs, parts of electric appliances, membrane switches, liquid crystal display (LCD), automatic vendors, name plates, print circuit boards, thick ICs.

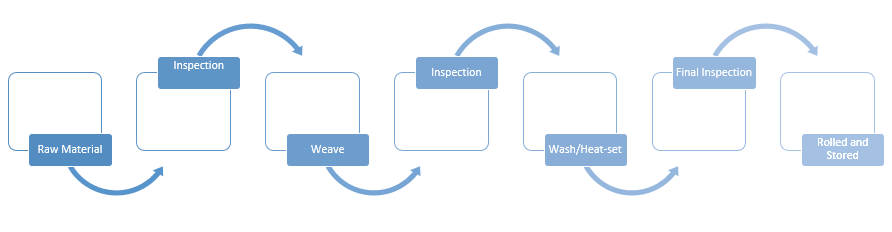

Production Procedure:

|

Mesh count (per cm/inch) |

Type of weave (TW or PW) |

Thread diameter (microns) |

Mesh opening (microns) |

Overall fabric thickness (microns) |

% Open area |

Theoretical |

Mesh Weight (gsm) |

|

8/20-300W |

PW |

300 |

950 |

560 |

57.8 |

323.5 |

169 |

|

10/25-260W |

PW |

260 |

739 |

498 |

54.6 |

272.0 |

158 |

|

12/30-140W |

PW |

140 |

688 |

256 |

68.2 |

174.7 |

55 |

|

15/40-200W |

PW |

200 |

465 |

353 |

48.6 |

171.5 |

141 |

|

18/45-180w |

PW |

180 |

375 |

330 |

45.5 |

145.5 |

128 |

|

21/54-140W |

PW |

140 |

333 |

250 |

49.0 |

122.5 |

96 |

|

24/60-120W |

PW |

120 |

294 |

210 |

49.7 |

104.3 |

81 |

|

|

|||||||

|

27/70-120W |

PW |

120 |

249 |

210 |

45.3 |

95.0 |

91 |

|

30/76-120W |

PW |

120 |

211 |

212 |

40.2 |

82.4 |

101 |

|

32/83-70W |

PW |

70 |

240 |

117 |

58.7 |

68.7 |

37 |

|

32/83-100W |

PW |

100 |

209 |

166 |

44.5 |

72.1 |

75 |

|

36/92-90W |

PW |

90 |

183 |

147 |

43.3 |

64.9 |

68 |

|

36/92-100W |

PW |

100 |

174 |

162 |

39.1 |

62.6 |

84 |

|

|

|||||||

|

40/103-80W |

PW |

80 |

166 |

133 |

44.1 |

58.6 |

60 |

|

43/110-80W |

PW |

80 |

149 |

130 |

40.8 |

53.0 |

64 |

|

45/115-80W |

PW |

80 |

138 |

130 |

38.7 |

50.3 |

67 |

|

48/123-80W |

PW |

80 |

122 |

130 |

34.5 |

44.8 |

72 |

|

48/123-55W |

PW |

55 |

151 |

90 |

52.8 |

47.5 |

34 |

|

51/131-70W |

PW |

70 |

121 |

114 |

38.1 |

43.5 |

58 |

|

54/137-64W |

PW |

64 |

115 |

103 |

38.7 |

39.8 |

51 |

|

61/156-64W |

PW |

64 |

90 |

101 |

30.1 |

30.4 |

58 |

|

68/175-55W |

PW |

55 |

85 |

87 |

33.5 |

28.4 |

48 |

|

68/175-64W |

PW |

64 |

78 |

98 |

28.2 |

27.6 |

65 |

|

71/180-55W |

PW |

55 |

79 |

90 |

31.5 |

28.4 |

51 |

|

77/195-48W |

PW |

48 |

77 |

80 |

35.0 |

28.0 |

42 |

|

|

|||||||

|

77/195-55W |

PW |

55 |

67 |

87 |

26.5 |

23.3 |

55 |

|

82/206-48W |

PW |

48 |

68 |

79 |

30.8 |

24.3 |

44 |

|

90/230-40W |

PW |

40 |

68 |

65 |

37.6 |

24.4 |

33 |

|

90/230-48W |

PW |

48 |

55 |

78 |

24.6 |

19.2 |

49 |

|

100/255-40W |

PW |

40 |

57 |

64 |

32.5 |

21.1 |

37 |

|

|

|||||||

|

110/280-34W |

PW |

34 |

54 |

55 |

35.2 |

19.3 |

31 |

|

110/280-40W |

PW |

40 |

47 |

65 |

26.6 |

17.3 |

40 |

|

120/305-34W |

PW |

34 |

45 |

55 |

29.6 |

16.3 |

34 |

|

120/305-40W |

PW |

40 |

37 |

64 |

20.1 |

13.0 |

44 |

|

130/330-34W |

PW |

34 |

40 |

55 |

26.9 |

14.3 |

37 |

|

140/355-34W |

PW |

34 |

31 |

55 |

19.4 |

10.6 |

39 |

|

150/380-34W |

PW |

34 |

23 |

55 |

12.1 |

6.6 |

42 |

|

165/420-27W |

PW |

27 |

29 |

43 |

22.3 |

9.6 |

29 |

Fabric number

The fabric number is composed of:

Mesh-count n 110-80W PW Thread ∅ dnom 110-80W PW Fabric colour 110-80W PW

(White = W; yellow = Y) Type of weave 110-80W PW (Plain Weave = PW